Seit Jahren baut WKV sowohl projektspezifisch als auch projektunabhängig auf kontinuierliche Forschung und Entwicklung. Zusammen mit jahrzehntelagen Erfahrung bietet uns dies die notwendige Sicherheit, zuverlässig Spitzenwirkungsgrade garantieren zu können.

RESEARCH AND DEVELOPMENT

RESEARCH AND DEVELOPMENT

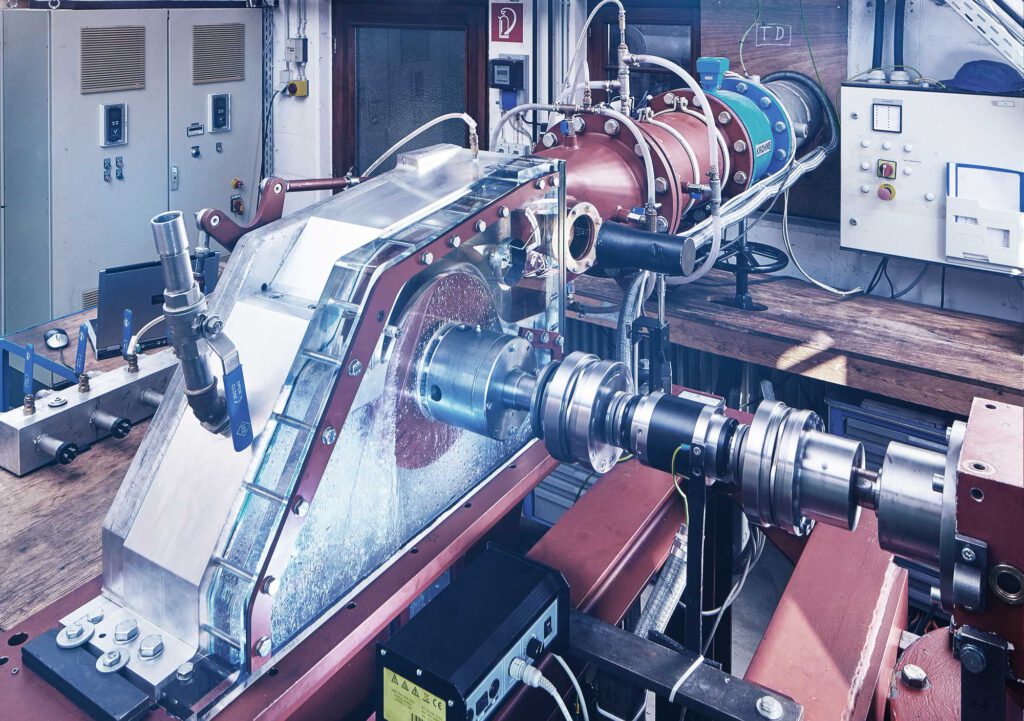

Since WKV was founded, a large part of our profits has gone into research and development. As a result, we are today among the best in our field worldwide.

WKV turbines are continually improved and upgraded in our own research and development laboratory in Simonswald. A common factor for all our products is the first-class quality. In our laboratory, we demonstrate this regularly and by far have achieved the highest efficiencies and long service life.

Our lead in technology is preserved by these continued improvements. Also our electronic components are perpetually improved, considering practical experience.

All modifications at our controllers are, in order to simplify service and replacement work, performed backward compatible. This grants a proper parts service over the entire life-time of the power plant. Furthermore, we ensure that even old electronic controllers can be replaced by new equipment with far better or extended performance within minutes.

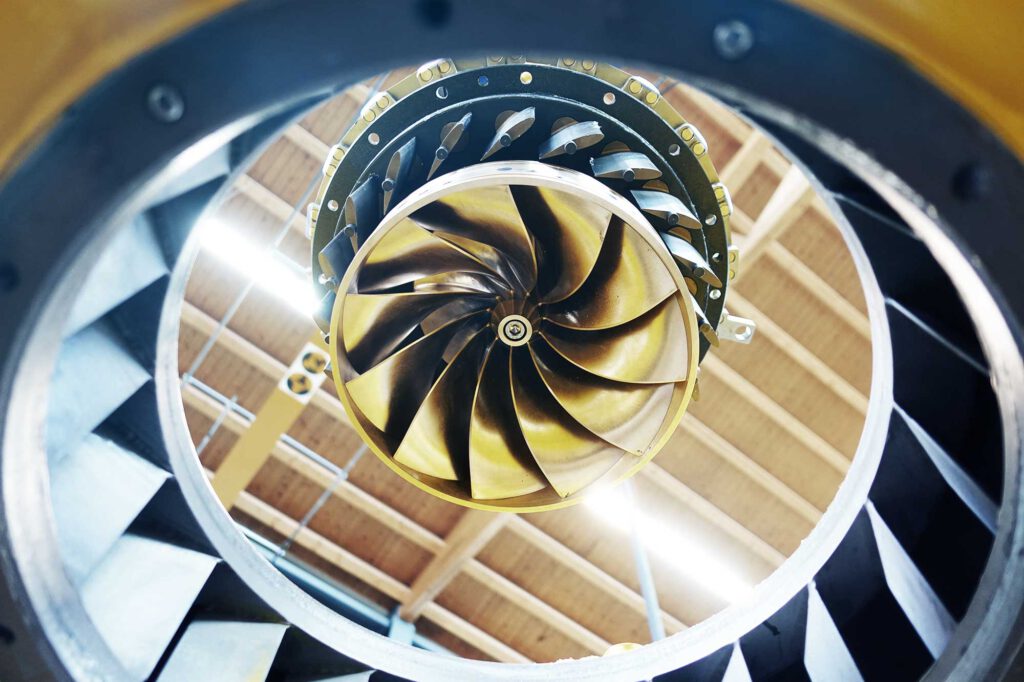

FRANCIS TURBINE

A wide operation range with high efficiencies and reliable dimensioning for an operation time of centuries. A WKV – Francisturbine has to fulfil a lot of requirements. Extended flow simulation, FEM – analysis of all main turbine components together with broad experience in model and prototypes guarantees the high technical level of a WKV – Francis turbine.

IMPULSE TURBINES

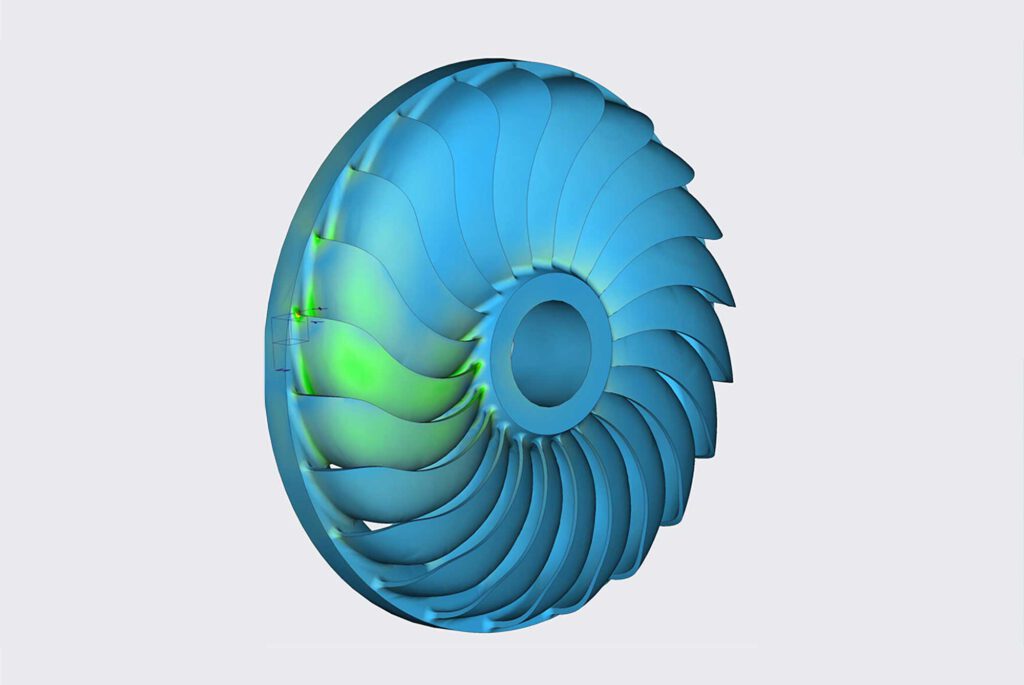

The highly transient flow, characteristic of Pelton and Turgo turbines, demands precision in development and construction of the single hydraulic components. Since years ago, WKV focuses on modern software tools to adapt the hydraulic components in the best possible way according to the specific project requirements. In the heart of the turbine, a full parametric CAD model of the runner guarantees the highest precision in construction, flow, and from the FEM analysis to the CNC machining.

PELTON TURBINE

TURGO TURBINE

CROSSFLOW TURBINE

The compact solution for turbines up to 3 MW also benefits on the steps of innovation made in the last years. Transient flow simulation as well as FEM – analysis using unsteady - cyclic load approach, of course also tested and optimized in our laboratory.